{Prologue: It is quite interesting to recall – my memory jogged by reading endless back issues of Subsea Engineering News – the unconstrained enthusiasm for new technology back in the mid 1980’s when subsea production was still very new and seen as the next big thing.

So much money was thrown at the development of new equipment and systems through what appeared to be an endless series of new R&D programmes. It seemed like every week, another big operator was launching its own effort and throwing tens of millions of some currency – pounds, dollars, krone, euros, et al – at various operational challenges.

There was so much self belief – and the perceived need for secrecy surrounding technology – that there was hardly any collaboration amongst operators except occasionally when an idea, harebrained or not, was proposed by an engineering company or hardware manufacturer. The only real winner must have been those intrepid linguistic specialists who came up with the various acronyms coined for these projects. Without trying to remember what all of the acronyms meant, ‘D’ usually meant diverless or maybe deepwater, ‘U’ was underwater, ‘M’ was for modular but maybe multiphase, SPS was subsea production system, etc.

Some of the international operators even had multiple schemes running either in parallel or in series. For example, Elf Aquitaine, as it was back then, started with Clustoil and then ventured into Skuld and Super-Skuld. Mobil was very enthusiastic about SAS, but then ended up supporting Statoil’s own UPS, some of which ended up as part of the Statfjord Satellites project (more on this later). Statoil was also a major sponsor of the multiphase technology programme Poseidon which was predominantly French (IFP, Total, et al). Shell had its own in-house project DIMOS, but also spent a good deal of money on SMUBS, the multiphase pump development by Framo that ended up being used at Draugen.

Probably the biggest R&D ‘black hole’ was BP DISPS – which followed on from earlier study work known as DITEMA (diverless template-manifold) and NASPS (novel automated subsea production system). If I remember correctly, the only achievement of DISPS, for an investment of tens of millions of pounds, was an rov-deployable insert choke valve. It is not surprising that there was a ‘night of the long knives’ in the early 1990’s, after John Browne took over, which saw many subsea specialists given their marching orders.

Even more notorious was GASP, a technology project promulgated by Goodfellow Associates. A number of operators were caught up in this project which never resulted in any substantive achievement and Scottish Enterprise almost ended up sponsoring a test programme that never happened.

One bit of technology that was continually debated at this time was tfl or through-flowline downhole tools deployment. Any number of operators thought it a very good bit of capability to have at hand – ie the ability to pump tools down a well without a vessel or rig – while others saw it as an expenditure that could be left out of the development budget and moved to operations. Just another example of teams from the same companies pulling in different directions.

And just to stimulate some memories, I will mention a few names which I came across that might make some folks say, ‘whatever happened to…’ : Mike Harkrider, Donal O’Neill, Jim Rumley, Tim Kieft, Roger Dyer, Keith Dallard, Pat Fontaine, Ted Schultz, Chris Lawlor, Steve Duckworth, Tony Humphries, Egil Koch, Terry Mahoney, Brian Songhurst, et al. Something to think about during the (hopefully) final throes of lockdown this summer.}

Most, if not all, of the significant subsea developments and projects that took place in the North Sea in the 1980’s were in the UK sector, but Norway was already cranking itself up to takeover as the hot bed for innovation. So much so, that the government there created a body dubbed Innovation Norway. It was not meant to be all about the oil and gas industry, but as this sector was the biggest wealth creator this small country, whose economy was almost totally based on fishing until 1969, had ever experienced one can only assume that quite a good deal of its effort was directed there. There was even a very memorable survey done to determine where Norwegian companies should direct their technology/R&D efforts.

{Aside: in case you have not seen it, check out the Norwegian television series State of Happiness which is about the beginning of the oil business. Very good.}

If one mentions Norsk Hydro in Norway, what you might get are references to aluminum and, unfortunately, its work on heavy water for the Nazi atom bomb programme during WWII. From the oil sector, though, you more likely could get a sigh of remembrance of a company that did not seem daunted by any technical challenge. Obstacles were only there to be overcome, not to halt or block a development.

Hydro, has it was known, was ready to deploy Petrojarl 1 for early production at the Oseberg field (30/6, 30/9), but also knew of the need to import gas to keep reservoir pressure up at the field. But where to get it? The giant Troll field had already been discovered in adjoining Block 31/2 by Norske Shell, but a location to reach gas in another part of the Troll field was as far away as 50km, way beyond the longest tieback (13km) to date at Highlander, and in waters just beyond 300m, deeper than any development to date in the North Sea.

The first public mention of what would become TOGI, for Troll Oseberg Gas Injection, was in September 1985 at the Offshore Europe conference. Originally known as Troll Module, a concept first hinted even a year earlier, would undergo various iterations before it was finally fixed. Multiple templates, multiple phases, different types of xmas trees, et al, were all in the mix.

And yet it was not long – November 1985 in fact – before the final concept, developed under the watchful eye of Hydro’s subsea guru, Knut Varvin, with the assistance of some well known British expats, was finalised. It was to be a single six-slot template manifold – but with only five wells – with a 20in 5,000psi heavy walled (1.5in wall thickness) pipeline tied back 48km to the planned location of the main Oseberg platform. The price tag was to be NOK3.9bn in money of the day, but Hydro said at the time that the use of gas injection would reduce the platform well count by 20, saving NOK2bn in drilling costs.

Even at that juncture, there continued to be a debate about whether such a development could be successful and whether a floater should be looked at again. One Troll partner, Shell, firmly opposed the subsea solution and two others, Mobil and Conoco, were not keen on the whole idea. Even some Norwegians were against subsea, because all of the xmas tree technology lay in the hands of the American hardware manufacturers.

In the end, none of these objections, technological uncertainties nor economic issues halted this landmark project which influenced future developments, such as Shell Mensa and Statoil Snohvit, on the controls side. The TOGI controls contract went to Vetco Gray, or Hughes Offshore whichever it was called at that point, which had a joint venture with Aker and the support of NL Shaffer. And while the tieback distance was 48km, I believe that the signalling was proven over the round trip so actually nearly 100km. The xmas trees came from Cameron in joint venture with Kvaerner at the time. These jvs between the main hardware companies and the Norwegian engineering/fabrication companies were in constant flux.

There would be more than a few hitches on the way to first production – especially considering the extensive integration test programme – but the big stumbling block proved to be the pipeline connection at the field. The 20in pull-in in 305m was the deepest done at the time and also involved a very early use of an ROT, or remotely operated tool. The titanium sealing plate on the connector became fouled and could not be secured properly. In a significant piece of impromptu engineering, Kvaerner Brug came up with a tool that could clean the plate in situ which would allow the pull-in to be completed.

The project delay as a result of this issue was inconsequential. The first production well was completed in January 1991 and the field officially came onstream in February 1991 as expected to great acclaim. And rightly so too. Even with only four wells completed – the fifth had been damaged by a dropped tool and would not be completed until later – the field produced at 10.5mcm/d – or 370mcf/d – and by the end of the year was producing 13mcm/d, well beyond the technical and contractual level, for injection into the Oseberg reservoir.

At around the same time that Hydro was working on TOGI, Saga Petroleum was launching its own new large deepwater development, Snorre. Reading the reports at the time, Saga, the least experienced of the three Norwegian operators, looked at every possible development solution for this field and was being tugged in various directions by different forces.

The key moment in the project timeline was the decision to turn to Esso Norge as its technology adviser. It was a close run race, if I remember correctly, between Esso and Conoco. The latter company was only a few years beyond having installed the first tension leg platform in the UK sector at Hutton. A tlp would be chosen as the field centre, but there was quite a debate about steel versus concrete hulls. It would have been Conoco’s choice to use the latter as it was just about to launch into the Heidrun tlp project where it did use concrete, Norway’s favourite material. Saga chose to go with steel for that part of the development.

There had been talk of as many as 100 wells for the development, but the final decision was much less ambitious – 40 wells through the tlp and another 20 subsea, although only 10 – five producers and five water injectors – at a time. The subsea production system, developed by an conceptual and engineering team led by Esso’s subsea veteran Tom Childers, would be the third in a hereditary line that lead back through the UMC to the SPS. It was not exactly a copy of what had come before, but it was part of an evolutionary process.

The template-manifold was dubbed ‘the toast rack’, a term apparently coined by Kvaerner Engineering at the time which engineered the structure. One of the technology links was the manipulator-deployed tooling used for maintenance on the structure. Both the SPS and the UMC had employed an rmv (remote maintenance vehicle), but by late 1990, Shell had abandoned plans to deploy the rmv and sold the vehicle and the tools to Saga. The new operator scrapped the rmv – it was already two decades old – in favour of a new ro(for operated)mv, designed and built by EB Seatech with an active heave compensated systems supplied by Dyna Craft.

As with most these types of projects back then, it was haunted by a major failure. Here it was the cabling for the control system, supplied by Kongsberg Offshore. I always had my ear to the ground back then, but it never fully came to light what the problem was, although it was assumed to be water ingress. In any event, the full complement of cabling had to be retrieved and replaced which at least proved the efficacy of the remotely-operated maintenance system.

Looking back at what took place at Snorre, the biggest issue had nothing to do with any equipment, but with reservoir analysis. The reserves were a big multiple of what was estimated at the time – although this was not that unusual back then – which has resulted in at least two subsequent redevelopment schemes to recover the oil in place.

So what about the 500lb gorilla in the room, better known as Statoil? The state-owned company was still in a growth period in the early 1990’s, but it was the biggest Norwegian player at the time. So with Hydro doing TOGI and Saga on Snorre, what was Statoil doing subsea?

Of course, the short answer actually is everything. It was a partner on both earlier projects and so knew exactly what was going on. It was, for example, able to apply lessons learned and technology applied at TOGI for its Snohvit project in the Barents Sea. It is difficult to say what it learned from Snorre as no similar project has ever been attempted.

In parallel, Statoil was getting ready to launch its own first major subsea development, Statfjord Satellites Project, alternatively known as Statfjord East and North. It was also executing the Tommelitten gas project at around the same time, but that was not seen, at least from a historical perspective, to have been as important.

It is of some significance to note that SSP got caught up in a major political tangle. These two fields, like many in the Tampen area of the Norwegian North Sea, were not in single blocks, but crossed boundaries into several. Stat E was partially in the same block as Snorre and at this time, the Norwegian government, before the creation of Petoro, the entity which holds all state licence stakes, was still deciding which projects to participate in and what stake to take. Snorre was seen as potentially less profitable than Oseberg or Troll and the government took a long time to decide how to approach it – in fact, the government actually changed during the discussions.

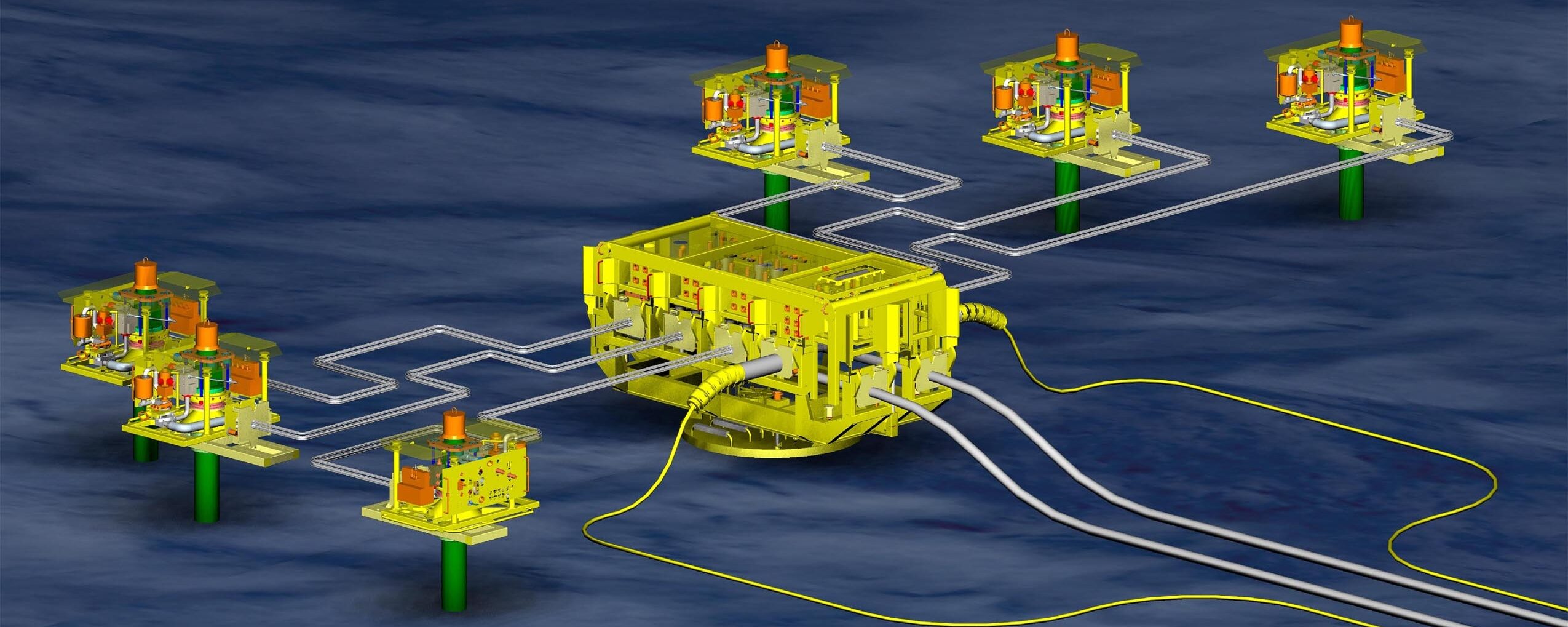

So what was notable about SSP? Even now, almost 30 years later, the idea of standardisation remains a contentious one, but Statoil went the whole hog. These two projects plus another, Loke, had a total of seven identical templates, some for production and some for water injection. Also, Statoil said at the time that it had learned a great deal from its experience with the Gullfaks subsea satellites and said that it expected to save 20-30% on the cost of drilling and completing the wells.

The other big technology leap was the first use of steel tubed umbilicals (STU), supplied by Alcatel, now Nexans. For those too young to remember, there was a major industry programme, dubbed Umbilicals The Future, executed in the early 1990’s. Operators were very concerned about a number of issues to do with umbilicals, but primarily methanol permeation through the walls of thermoplastic hoses. This led to the use of the STU’s, both to mitigate this problem, but later for deepwater developments to prevent hose collapse.

This project also led to a major marketplace realignment. I believe that this was the first project in which Kongsberg Offshore and FMC supplied hardware together. KO was on a winning streak, having secured controls contracts for Snorre, SSP and Draugen. In 1993, FMC bought KO, then part of Siemens, and transformed itself into the leading subsea hardware company, a market position it still holds today.

*************************

I think I will put the subsea history lessons on hold for the moment and go back to general commenting on the offshore sector. As The Terminator said, ‘I’ll be back.’

Also, I know that this is not a great time to be putting the squeeze on companies, but SubseaWatcher still needs financial support, ie advertising. I had 22,000 hits in the first year – not bad for a specialist blogspot – so maybe there are other companies looking to get their names out in front of this sector of the industry.