I have to admit that since I stopped publishing SEN fortnightly seven years ago, I am not quite on top of all of the technical issues as I formerly was. But as I often suggested in the past, the oil and gas industry is never the quickest off the mark to deal with its own shortcomings and so it continues.

It was with some dismay that I discovered several references recently to IOGP JIP33. For background, IOGP is the International Association of Oil & Gas Producers and JIP33 is a joint industry project to do with standardisation. Now I never had much contact with IOGP until the post-Deepwater Horizon period. I attended an IOGP technical event in The Netherlands that was meant to address many of the contentious issues that came to light in the aftermath of that environmental and human tragedy and it was one of the most surreal events I had ever been to. Two instances are worth mentioning. Firstly, I spoke to an executive from ExxonMobil who said to me that his company never thought that an event such as the Macondo blow-out could occur, because of the number of failsafe mechanisms inherent in modern drilling systems. So, we can look the other way, because our equipment can not fail. Huh, you might say. Essentially this equipment is perfect and we can discount human error. NOT! A message from another operator whose name escapes me now was that we know what we are doing and such an appalling event could not happen on our watch. I recall mentioning that the company had recently had several unfortunate international drilling near-accidents that year.

This made me pretty suspicious of activity that was created under the auspices of this organisation as it represents these among many operators. So what about JIP33. This programme of activity around standardisation began six years ago in response to what it called development cost and scheduling overruns of up to 40%. Was this a bad thing? Not in general terms, but such project issues had been flagged up years before this programme was started in 2016. So what took it so long? Beats me, but assume organisational inertia and pushback.

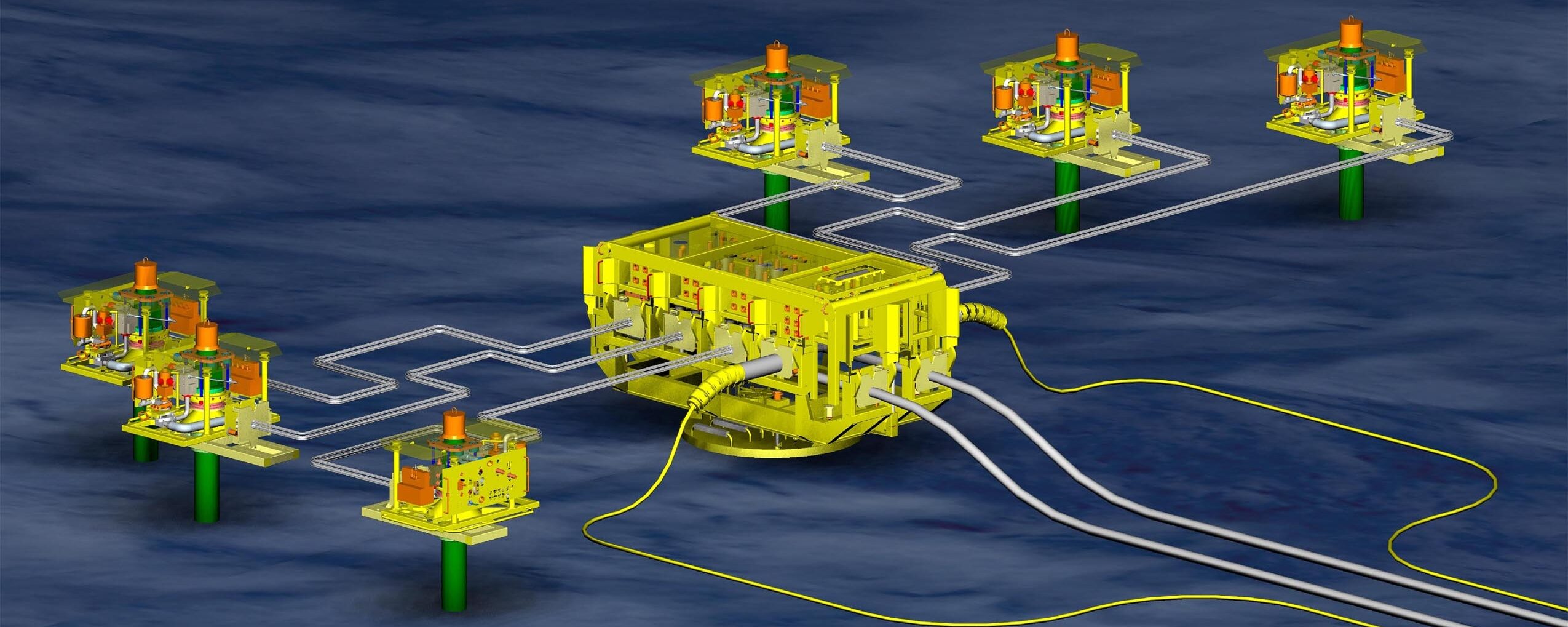

Then let us consider the entire issue of standardisation. Where has IOGP been for the last 30 years? Back in the early 1990’s, I ran two technical seminars addressing the issues of subsea standardisation. At the same time, API was dealing with a number of standardisation issues under the API-17 banner and has produced many documents on a variety of subjects, eg interfaces, subsea trees, connectors, control systems, et al, and even updated some of them a number of times. I can only assume that other areas have been covered by different API working groups. So who needs IOGP? A cursory look at what it had produced in one area – subsea trees – made me think that it was simply adding more documentation and oversight in some specific areas that are already covered in general terms and would already have been considered in production system engineering. It seems to me that IOGP has simply decided to stick its nose into areas that have already been looked at by others.

* * * * *

Now here is a story that was totally predictable – the announcement that the Chinese have produced their first in-country developed subsea tree. It was never going to be long before the Chinese stopped buying certain types of subsea equipment from American and European companies and producing them at home. Just wondering about the design and specifications and what was their basis. Do they plan to export such equipment and will anyone be able to assess their designs to ensure that they are totally different from what has been supplied before?

It must be at least 10 years ago that Bil Loth and I took the subsea production systems engineering course to Shenzen at the request of Husky Oil. As part of its production sharing contract, Husky had to provide technology transfer and our course was part of that exercise. We had a room full of engineers from CNOOC, which was the company making the announcement about the tree. We also had a site visit to see some of the hardware for what I believe was the Liwan 29/6 project. I am sure that OneSubsea (then Cameron) which supplied the subsea hardware for that first Chinese subsea deepwater gas project would love to get a look at these new Chinese trees. This is not to suggest that the Chinese could not produce equipment as technically sound as what has been manufactured before, but did they start from scratch? Something to ponder as the summer is about to begin.